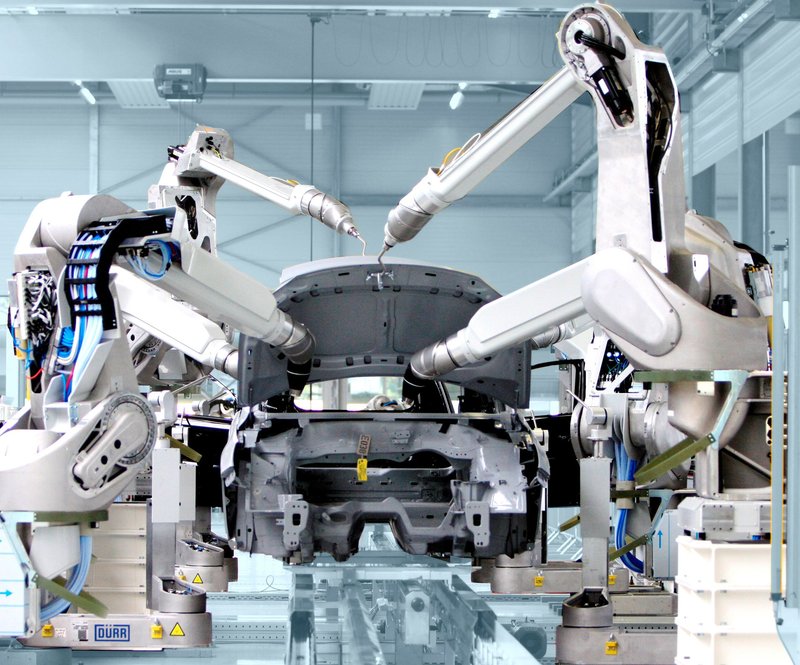

Collaborative robot automotive industryAccording to Universal Robots, if the quantity of industrial robots doubled, the number of personnel would also enhance. Collaborating with other robots: Big, standard industrial robots aren’t safe for humans to operate alongside. For this explanation, they are separated from people by heavy cages – but cobots can function closely with conventional robots without having fear, and therefore play an integral function on the automotive line. Cobots can feed components to an additional robot for painting or spot welding, with no risking the safety of a person.

As 1 of the first industries to wholeheartedly adopt automation, the automotive manufacturing sector has long benefited from successive improvements in robotics technologies. More than time, robots utilized in automotive manufacturing applications have become smaller, much more precise and far more multi-functional than their predecessors, making them indispensable in the production process. Nowadays, rising expenses linked with next-generation automotive supplies, skilled labor and security systems coexist alongside a require for manufacturing equipment to accommodate item changeovers. This makes a clear, compelling case for cost-powerful flexible automation options at every step of the automotive manufacturing procedure – from components, press and paint shops to assembly and inspection.

Material Removal : Due to the fact it can follow a complicated path repeatedly, a robot is an ideal tool for light trimming and cutting tasks. Examples contain cutting fabrics like headliners, trimming flash from plastic moldings and die castings, and polishing molds. Force-sensing technologies lets the robot maintain continuous pressure against a surface in applications like these.

Cobots Drive The Automotive Industry Forwardtypes of robots used in automotive industry

application of robots in automobile industry pptThe automotive industry’s demand for industrial robots is forecast to treble in the subsequent seven years, according to a new report. The progress of robots in the past 30 years has been wonderful. In truth, the progress in the previous year is something to brag about. Proof? Apart from taking a plant tour to any automotive assembly plant in the globe — specially in Japan — just variety robots” into any search engine on the Internet and get ready to scroll into one particular of the hottest research places in modern day instances. Even much more to the point, robotics and the Web will continue to be utilized in tandem.

Our three various collaborative robot arms are effortlessly integrated into existing production environments in the automotive and subcontractor industries. A robot arm from Universal Robots can be used in robotic car manufacturing systems just like any other auto manufacturing or automobile robot. They can be used in unsafe environments exactly where high good quality and precision are business-vital, such as engine foundries, laser-cutting rigs, forming presses, molding machines, and packaging and palletizing lines.

In the robotics space, we can see the same kind of distinction emerging: MIT not too long ago created a robotic cheetah,” meant to replicate the movements of its actual-life counterpart. It really is equipped with advanced sensors, an XBox controller, the ability to run at speeds of ten miles per hour, and jump about 16 inches high. It is an incredible piece of technologies.

Leading 4 Automation Technologies Used In Automotive Businesscollaborative robot automotive industry

collaborative robot automotive industryIn the final six years, (2010-2015), according to the IFR (International Federation of Robotics), US sector has installed about 135,000 new industrial robots. The introduction of helper robots is needed for German businesses, as are they are faced with a looming shortage of workers and an ageing population. In addition, German car makers are hoping new varieties of robots will spur productivity growth, as Germany’s automotive industry is beginning to fall behind South Korea, and is facing a possible threat from China.

It is the introduction of collaborative robots that is exciting a lot of producers now. The reduce in expense (an typical of $20,000) and the lighter, much more collaborative plug and play” generation of robots with advanced vision and sensor technologies are enabling business owners to augment their human workforces with robotic assistance. If a human gets in the way of a robot on the production line, it will just stop until its path is once more clear.

Automotive supply chains run lean with minimal inventory to buffer against production delays. Automotive portion manufacturers strive for consistent occasions, and consistent method handle in each step of the production line. Even the smallest dilemma can stop an assembly line. Robots don’t suffer end-of-shift fatigue, so cycle instances are continuous all day, each day, and peak production rates are constant. What’s more, operating robots by means of breaks and shift changeovers yields added output from production lines when compared to manually attended lines.

Robotized Assembly Method Using Dual Arm Robottypes of robots used in automotive industry

use of robots in automobile industryThe automotive industry’s demand for industrial robots is forecast to treble in the next seven years, according to a new report. Several jobs in automotive manufacturing are hazardous. Often, the dangers are obvious, as when pouring molten metal in a foundry. Other instances, they are more insidious, like the musculoskeletal issues resulting from lifting, twisting and repetitive motions. Robots can prevent these dangers to humans. In auto assembly, robots keep workers from exposure to fumes from welding and painting, as properly as weld flash and the noise of stamping presses. Automotive robotics cut accidents and injury claims by removing workers from these dirty and harmful tasks by removing them from these environments.

Premium car makers in Germany are offering highly individualised models in comparatively low volumes. Higher levels of individualisation develop excellent complexity, for instance Audi stated that its 1,200 suppliers provide 56,000 various components to its Neckarsulm facility. Such complexity demands dexterity and problem-solving expertise, something that robots are not capable of, as a result keeping German automobile manufacturers heavily dependent on human workers.

From tending stamping machines and manning body and frame assembly stations to applying precise coats of paint and sealing sensitive completed components, automakers and parts makers count on nimble, adaptable automotive robots to improve productivity and good quality. Kawasaki robots can efficiently execute dashboard assembly, engine, transmission and crankshaft handling and waterjet cutting for carpeting and other soft supplies. Meanwhile, important improvements in sensing and calibration technologies make our robots ideal for welding – including arc, spot and friction spot joining – vehicle and truck bodies as well as palletizing and crating parts and materials for delivery.