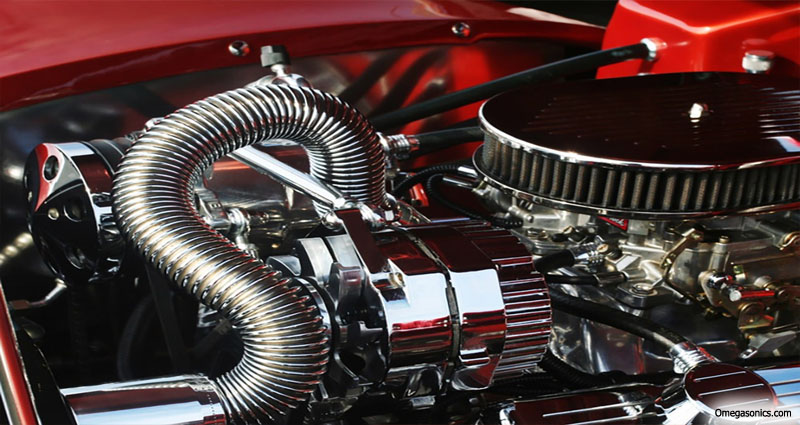

There’s anything magnificent about a beautifully restored antique classic automobile. 1 look beneath the hood of a 1930 Model 734 Packard Rumble Seat Roadster or one thing like Amelia Earhart’s’ 1931 Reo and you must think, “They sure never make them like that anymore!”

Whilst numerous of us can’t afford the classic cars of the 1920s or 30s some like to perform on old engines, coaxing new life into a recalcitrant block of 4, 6, or 8 cylinders as a component of our auto restoration project. Due to the fact it has to run to possess worth, an automobile engine is normally 1st to become tackled. An ultrasonic cleaner may be the best friend a restoration fanatic can have to get a project like this.

Ultrasonic cleaners are broadly used to clean engines of most any size and shape. They replace the old-fashioned solvent degreasers used in neighborhood garages of yesteryear. Possibly you recall seeing mechanics holding engine parts under a faucet and manually scrubbing away grit, grease, and grime as the solvent is re-circulated by way of a filter-equipped holding tank.

Now mechanics place disassembled engine parts in an ultrasonic bath. Yes, we’re speaking carburetors, fuel pumps, oil pumps, pistons, connecting rods, crankshafts, camshafts, bearings, all the many gears, chains, and elements that with each other comprise an internal combustion engine and for that matter, transmissions and differentials as well. The magic of cavitation does operate quicker, far more efficiently, and safely than any quantity of hand scrubbing in a volatile solvent.

Why an Ultrasonic Cleaner Cleans so Clean

Just like the old solvent cleaning system an ultrasonic cleaning system consists of a tank that holds the ultrasonic cleaning option. Biodegradable and secure, the options normally are available in concentrated kind and are diluted to manufacturers’ specifications. In addition to the tank, an ultrasonic cleaner consists of an ultrasonic generator and ultrasonic transducers that can be firmly attached to the bottom or sides of your tank.

When the unit is turned on the ultrasonic transducers create billions of microscopic bubbles in the cleaning solution. Engine components are placed within a mesh basket, on a rack, or otherwise suspended within the option and the cleaning cycle starts as the bubbles implode with tremendous force upon contacting the parts. Dirt, grime, grease, carbon deposits – all contaminants are stripped off of your components devoid of damaging them.

So tiny are the cavitation bubbles that they penetrate cracks, crevices, and blind holes – areas not possible to attain by manual scrubbing.

At the end of the cleaning, cycle parts are removed, rinsed, and dried. A rust inhibitor is applied and also the parts are ready for reassembly.

Operating Recommendations

Since it contains air, a fresh ultrasonic cleaning solution really should be degassed by letting the cleaner operate in a degas mode for no less than 10 minutes before immersing the components into the answer. This is since air bubbles interfere with cavitation action and slow the cleaning method.

Oils and residues that rise to the surface ought to be skimmed off and safely recycled. Filters can trap other contaminants and really should likewise be safely disposed of. Utilized biodegradable options might be disposed of in sanitary drains. The tank itself really should be periodically cleaned in line with manufacturers’ suggestions.