How are robots used in the car industryIn the final six years, (2010-2015), according to the IFR (International Federation of Robotics), US market has installed around 135,000 new industrial robots. 26. This segment largely involves spot welding and arc welding which is mainly used by the automotive market. Spot welding is nonetheless more po pular than robotic arc welding but not for long; as arc welding is becoming very well-liked in the me tal market. Much more tiny perform shop are starting to introduce welding robot into their pr oduction. In fact, with the cost of robot going down and the various tool now offered on the m arket, it is now less difficult to automate a welding approach.

Car manufacturing robots decrease element-to-part variability. Highly repeatable, they never ever tire or get distracted, so each cycle is performed the identical way. Neither do they drop components or manage them in a way that causes harm. That reduces waste previously brought on by human error, and it also indicates significantly less variability in vehicle assembly. Equipped with vision systems, automotive robots can even detect variation in incoming components and adapt their programmed paths to suit. This, in turn, translates to greater consumer satisfaction, fewer blunders and decrease warranty expenses.

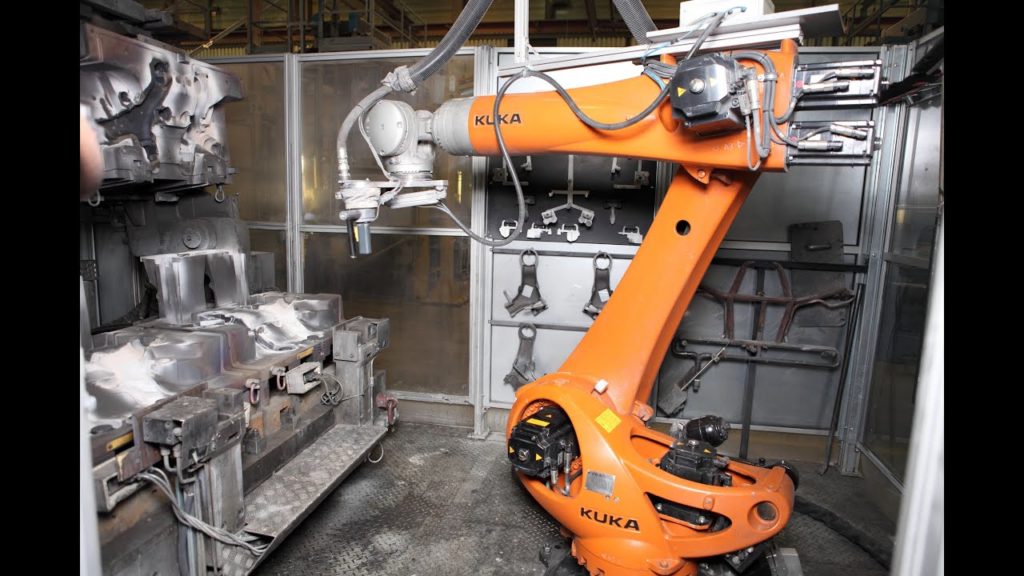

Universal Robots has 3 collaborative arms that integrate properly with any of the existing environments in subcontractor and automotive industries. Automobile manufacturing systems use the Universal Robots manufacturing robots the exact same way as other automobile and automobile manufacturing robots. The robots are versatile and versatile and they perform well in any atmosphere and situation. Examples of circumstances that Universal Robots manufacturing robots manage with ease are when cutting laser rigs, creating engine foundries when machines need to have molding, when forming presses, and in packaging and working on palletizing lines.

Demand For Industrial Robots To Treble In Automotive Markethow are robots used in the automotive industry

how are robots used in the car industryIn the final six years, (2010-2015), according to the IFR (International Federation of Robotics), US business has installed about 135,000 new industrial robots. The man-machine partnership will assume a crucial part in advancing intelligent production visions (Industry four.). Here, user-friendly robots are opening up opportunities for automation in differing sectors. The future potential of these robots is emphasized by comparing robotic density across a variety of sectors. For example, the Japanese automotive industry has a record 1,520 industrial robots per ten,000 staff. The equivalent quantity in all other industries is just 214 units. Germany and the USA show a related picture.

From tending stamping machines and manning physique and frame assembly stations to applying precise coats of paint and sealing sensitive completed elements, automakers and components companies count on nimble, adaptable automotive robots to boost productivity and good quality. Kawasaki robots can successfully execute dashboard assembly, engine, transmission and crankshaft handling and waterjet cutting for carpeting and other soft components. Meanwhile, key improvements in sensing and calibration technology make our robots ideal for welding – including arc, spot and friction spot joining – vehicle and truck bodies as nicely as palletizing and crating components and components for delivery.

Schwandorf is 1 of BENTELER- Enterprise’s 161 places. In Schwandorf, mainly automotive elements are manufactured, i.e. axes- and engine carriers. The competence of BENTLER is not only based on the production. The automotive supplier and improvement companion supports its customers worldwide alongside its complete provide chain. The strength of the division lies in the deep understanding of light constructional elements – related to material, style and processes. Basis for this knowledge is traced back to the different raw components such as steel, aluminum, fibre composite and synthetic material as well as the process know-how about customer items. The topic Industry 4. has been driving BENTELER ahead for several years now. Hereby, the digitization of the manufacturing processes of the entire provide chain is covered.

Prime 5 Robotic Applications In The Automotive Sectorhow are robots used in the car industry

how are robots used in the car industryIn the final six years, (2010-2015), according to the IFR (International Federation of Robotics), US business has installed around 135,000 new industrial robots. The automotive and sub-contractor manufacturing industries are today getting a significant facelift by investing heavily in robotics. This trend has seen many manufacturing firms get the significantly-required push-up they require to create far more and far better high quality automobiles. Universal Robots is on the forefront in making this attainable by creating collaborative robotic arms that add security and flexibility to each line of automotive production. The robots bring more worth to the item and make the manufacturing method less complicated to achieve.

In the context of the new Industrial revolution, OEMs and factories are turning towards open source architectures and moving away from proprietary solutions to deal with the speedy and asynchronous new developments in fields like processors, connectivity, mechatronics, Artificial Intelligence and enhanced reality. Openness also types the core of Sector 4. with robotics no longer a very good to have, but a need to-have” in Indian manufacturing.

While RPA is currently being used by automobile manufacturers, the application of RPA within the automotive industry is only anticipated to turn into far more universal and diversified in the future. Furthermore, a McKinsey & Company report suggests that 1 of the most disruptive technologies by 2025 is anticipated to be the automation of understanding work with the assist of RPA. Particularly, the improvement of RPA alongside other automation technologies (e.g. artificial intelligence, computer vision) will help to drive advancements to the automotive industry’s existing operations as well as developments to autonomous and close to-autonomous automobiles.

Cobots Drive The Automotive Market Forwardhow are robots used in the automotive industry

how are robots used in the car industryThe automotive industry’s demand for industrial robots is forecast to treble in the next seven years, according to a new report. The U.S. economic recovery also masks the urgency of the automation question. Auto sales hit an all-time higher of 17.55 million units last year. U.S. auto plants are running complete-tilt and employment in the business has ticked up as well. Nick Kottalis, a trade union leader at a Ford truck factory, thinks the company has weathered the crisis and is now rising employment thanks to the hard function of men and women, not robots. “People on production lines work so hard – 10 to 11 hours each single day – to make their living,” Kottalis mentioned with pride.

A lack of robots and higher labour charges puts the German auto industry at a disadvantage against its foreign rivals. As of 2015, Germany was the third biggest auto producer in value and fourth largest in volume. Germany’s global worth share, however, declined from 13% in 2010 to ten% in 2015 due to escalating production in Asia and the US.

He is not totally comfy with the pace of change. “It takes time for individuals to adapt and adjust and to learn new expertise. This is the significant issue,” he stated. Pratt and other researchers say the existing wave of automation sweeping through industry is diverse, even although the procedure has been going on for decades. Pratt is a former robotics group leader at the Defense Advanced Research Projects Agency, portion of the U.S. Division of Defense.